Waste Paper Pulp Molding Euipment Rotary Egg Tray / Egg Box Machine

Descriptions:

1. This is a Fully Automatic Egg Tray Production Line, range from 3000~10000pcs/h.

2. This production line includes a hydrapulper system, a rotary type forming machine, a single layer drying line, and corollary equipments.

3. Mainly used for egg trays, fruit trays, egg boxes, cup carriers and disposable medical care products and etc.

4. The raw material is the waste paper, waste carton, used paper, books, magazines and etc.

5. It’s high-efficiency, energy-saving, durable, wieldy and safe.

Specifications:

|

Model Type

|

ER3000-A

|

ER4000-A

|

ER5000-A

|

ER6000-A

|

|

Capacity

|

3000pcs/hour

|

4000pcs/hour

|

5000pcs/hour

|

6000pcs/hour

|

|

Workshop Requirement

|

500m2

|

600m2

|

700m2

|

800m2

|

|

Electricity Consumption

|

~120kw

(180kw installed)

|

~160kw

(250kw installed)

|

~200kw

(300kw installed)

|

~220kw

(360kw installed)

|

|

Material Consumption

|

180~210kg/h

|

250~280kg/h

|

320~350kg/h

|

360~400kg/h

|

|

Water Consumption

|

600~800kg/h

|

800~1000kg/h

|

1000~1200kg/h

|

1200~1400kg/h

|

|

Worker Requirement

|

4~5person

|

4~5person

|

4~5person

|

5~6person

|

|

Container Requirement for Shipment

|

6 x 40HQ

|

7 x 40HQ

|

8 x 40HQ

|

9 x 40HQ

|

|

Forming Machine

|

Rotary type with 8 plates. Each for 3pcs/time

|

Rotary type with 8 plates. Each for 4pcs/time

|

Rotary type with 8 plates. Each for 5pcs/time

|

Rotary type with 8 plates. Each for 6pcs/time

|

|

Drying Production Line

|

42mx2.2mx3.6m

|

42mx2.6mx3.6m

|

42mx3.0mx3.6m

|

42mx3.4mx3.6m

|

|

Remarks:

1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 65g~70g).

2. Workshop size is for reference only and could be adjusted according to actual size of client’s plant.

|

Fuel Consumption for Dryer (Can choose one of the below fuel):

|

Type

|

ER3000-A

|

ER4000-A

|

ER5000-A

|

ER6000-A

|

|

Natural Gas

|

60~70m3/h

|

80~90m3/h

|

100~110m3/h

|

110~120m3/h

|

|

LPG

|

21~24m3/h

|

28~32m3/h

|

35~39m3/h

|

40~45m3/h

|

|

Diesel

|

50~60kg/h

|

68~76kg/h

|

85~92kg/h

|

95~100kg/h

|

|

Heavy Oil

|

52~62m3/h

|

70~80kg/h

|

88~95kg/h

|

98~105kg/h

|

|

Steam

|

1.1~1.3ton/h

|

1.4~1.6ton/h

|

1.7~1.9ton/h

|

1.9~2.2ton/h

|

|

Wood

|

210~240kg/h

|

280~320kg/h

|

350~390kg/h

|

400~450kg/h

|

|

Coal

|

140~160kg/h

|

180~210kg/h

|

220~250kg/h

|

260~300kg/h

|

Production Processes:

Pulping System: |

Waste paper will be made into pulp with certain concentration through pulping screening and grinding.Including: pupler, grinder, pulp tank, water tank, pulp pump, water pump, agitator, consistency and control cabinet. |

| Forming System |

The pulp is vacuumized into products on forming mold, then products are transferred to dryer automatically. Including rotary forming machine, vacuum auto drain system, auto cleaning system for the forming mold, preheating system and auto control cabinet. |

| Vacuum System: |

Supply vacuum for forming machine. |

| Air Compressor System: |

Supply compressed air for forming machine. |

| Drying system: |

Single layer dryer, one burner Italian brand. The energy for option: LPG, natural gas, diesel oil. Steam, coal, wood and etc.

|

| Stacking System: |

The finished products will be counted and stacked automatically after drying.

|

YOUTUBE Links:

3000pcs/h with single layer dryer: https://www.youtube.com/watch?v=CX9NgjBZ0Nk

4000pcs/h with single layer dryer: https://www.youtube.com/watch?v=JCu3xNpnCsM

6000pcs/h with single layer dryer: https://www.youtube.com/watch?v=9XpyL-ggwi4

4000pcs/h with 6 layers dryer: https://www.youtube.com/watch?v=85eeIP8xCEY&t=3s

6000pcs/h with 6 layers dryer: https://www.youtube.com/watch?v=YIeLPQnwO4M

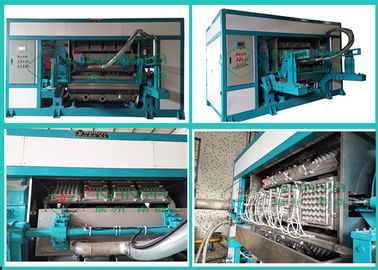

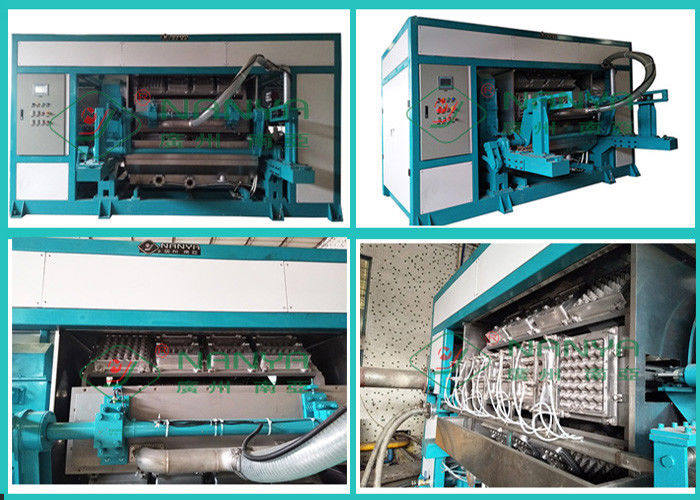

Main Machine Picture:

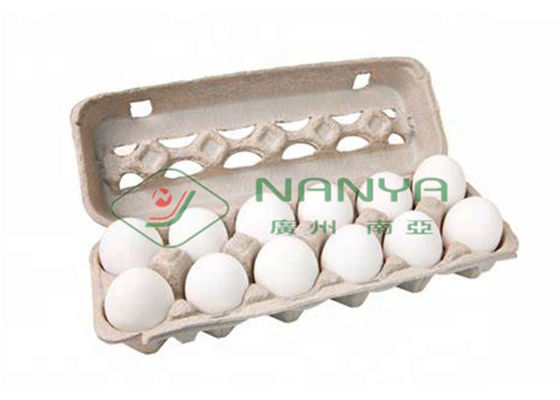

Finished Products:

1. By changing molds, the machine can make egg trays, fruit trays, egg boxes, cup carriers and disposable medical care products and etc.

2. The below is one type of egg box made by this rotary machine:

Business Terms:

| NO. |

ITEM |

DESCRIPTION |

| 1 |

Payment Terms |

Can accept T/T, L/C, Cash, or Western Union |

| 2 |

Delivery Terms |

FOB, CNF or CIF terms |

| 3 |

Delivery Time |

100 days |

| 4 |

Packages |

Strong and Suitable for Marine Shipment |

| 5 |

Installation |

Supplier should appoint 2 engineers to instruct buyer in installation, test-run and training |

| 6 |

Warranty |

Life-long service, sustainable supply and upgrade machine and parts. 12 months warranty( three-year warranty for mechanical parts and main machine) |

NANYA Advantages:

1. Established in 1994, with 30 years of expertise and experience, NANYA is one of the earliest manufacturers for Pulp Molding Products in China;

2. Combined with high and new technology with government institution and South China University of Technology, with over 30 R&D personnel;

3. NANYA offers the widest range of both equipment/machine types and platen/tooling sizes, as well as the comprehensive molds;

4. NANYA factory covers an area of 40,000 square meters, contributing to more than 60% of the domestic demands, already exported to over 80 countries and regions;

5. Excellent engineers, sales and after sales service team brings the best service to ensure long-term satisfaction for our customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!